Completion Equipment

Completion equipment are that equipment which are used to bring an oil well to the completion state so that first test production and later commercial production can be started from it. In general terms, any equipment that is used in the development of well and after that in the completion process can be referred to as completion equipment. Our tools enable operators to improve the performance of the reservoir while achieving higher extraction ratios, reducing capital expenditure, saving time, and increasing production.

Seal Bore Extension

Seal Bore Extension is used in completions where a seal bore packer is used as a production packer and tubing movement is expected. Seal Bore Extension provides sufficient seal bore length so that long seal assemblies accommodate tubing movement while always remaining in the seal bore. Multiple seal bore extensions can be coupled together using a concentric coupling to obtain more seal bore length. Seal Bore Extensions are available for all sizes of seal bore packers. Seal Bore extensions are manufactured from materials that comply with NACE MR0175 STD. For SSC-resistant metallic material.

Polished Seal Bore Receptacle

The PARVEEN Polished Seal Bore Receptacle is designed for applications where a large ID must be maintained through the completion while accommodating extreme tubing movements. The PARVEEN Polished Seal Bore Receptacle modular design allows tool to be easily converted from tension release to hydraulic release. The tension release and the hydraulic release incorporate a Polished Seal Bore Receptacle as well as a PBR seal assembly including 2 sets of working seal units and a debris barrier above and below the working seals. Both versions when combined with a hydraulic or hydraulic/ hydrostatic set can be run in and set in one trip.The polished seal bore receptacle can be retrieved in two trips.The seal assembly is retrieved when the tubing string is recovered. The PBR seal bore is retrieved with a PBR retrieving tool. The Polished Seal Bore Receptacle is available in varying lengths of up to 25 ft. in stroke. An adjustable shear mechanism locks the outer housing and seal mandrel together during run-in. Once the seal assembly is released, it is free to move in the bore, compensating for tubing movement. The PBR assembly can be pinned in the fully stroked, closed or midway position to accommodate pre-spacing in one-trip completions.

Its Featured include-One-piece polished bore housing. Full bore-seal mandrel allows passage of intervention tools.Adjustable shear-release mechanism. Available with premium materials and connections.Available in stroke lengths up to 25 ft..Metal-to-metal connections for hostile environments. Debris barrier above and below seals for long life. Seals are retrieved on the tubing string.Threaded receptacle on top for PBR retrieval on workstring.

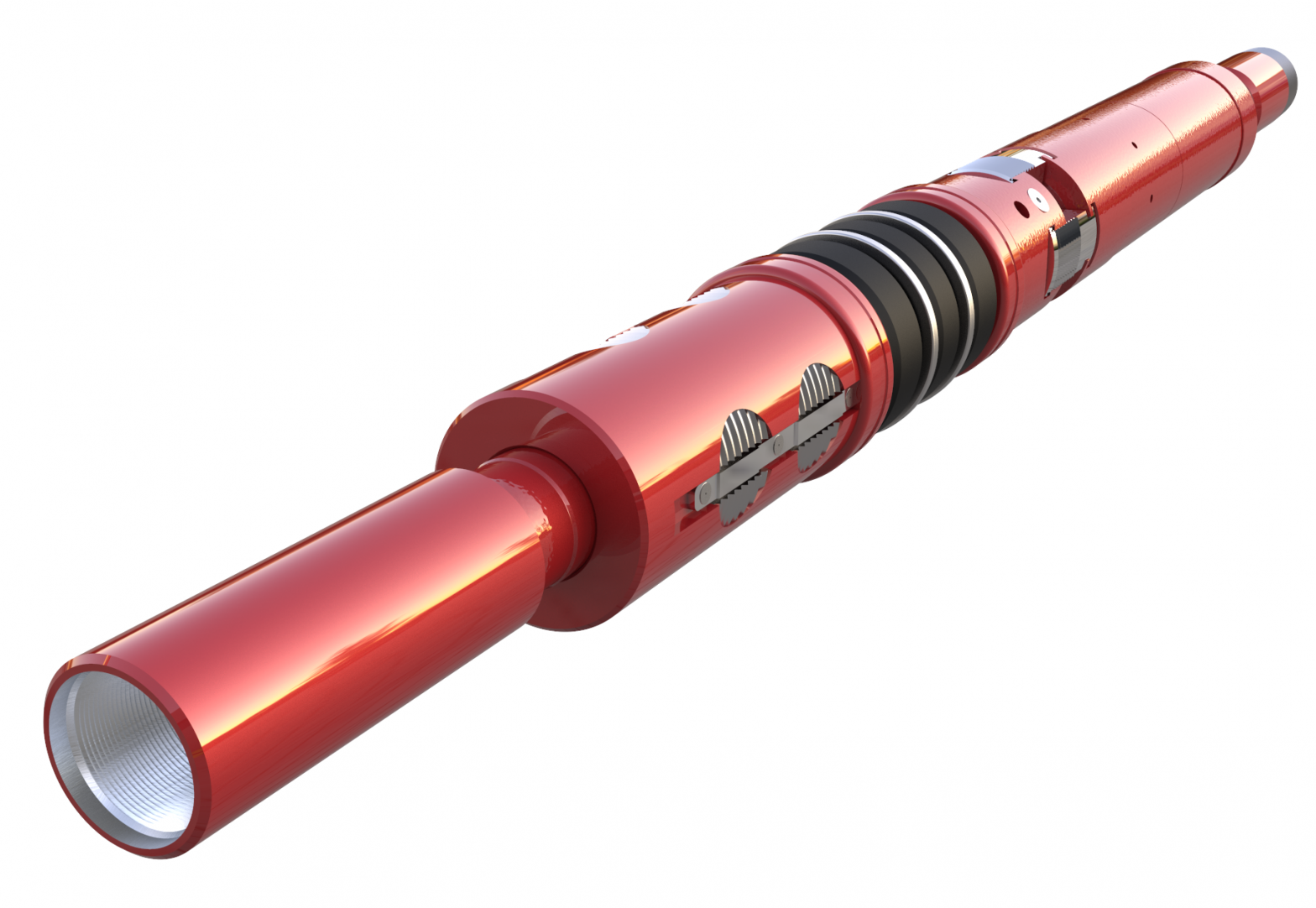

AD-1 Tension Packer

The PARVEEN AD-1 Tension Packer is a retrievable, single grip tension-set packer, used in waterflood, oil production, or treating applications. This compact, economical packer is used for shallow wells where sufficient set down weight is not available to utilize a set down packer. It is set by left-hand rotation and has three release methods.

Its Features include- Sets securely in any hardness casing, including premium grades. Compact, short, easy to transport and run. Full opening enables maximum fluid circulation. Rocker-type slips eliminate the need for extra drag block. Easy to operate – a simple and reliable J-Slot mechanism, actuated from the surface by tubing rotation, makes the packer easy to set and release.One-piece packing.Three release methods, normal release, shear release, and safety joint release.

AS1-X Mechanical Packer

The PARVEEN AS1-X Packer is the most versatile of the mechanically set retrievable packers and may be used in any production application. Treating, testing, injecting, pumping wells, flowing wells, deep or shallow, the AS1-X is suited for all. The packer can be left in tension or compression, depending on well conditions and the required application.A large internal by-pass reduces swabbing when running and retrieving.

Its Features, Advantages and Benefits include-The design holds high differential pressure from above or below, enabling the packer to meet most production, stimulation, and injection needs.The packer can be set with compression, tension, or wire line, enabling deployment in shallow and deep applications. The packer can be set and released with only a one-quarter turn of the tubing. The bypass valve is below the upper slips so that debris is washed from the slips when the valve is opened, reducing the times for circulation and total retrieval. The full opening enables unrestricted flow and the passage of wireline tools and other packer systems. The packer can be run with the T-2 on-off tool, which enables the tubing to be disconnected and retrieved without retrieving the packer.

AS1-XHP Mechanical Packer

The PARVEEN AS1-XHP Packer is the most versatile of the mechanically set retrievable packers and may be used in any production application. Treating, testing, injecting, pumping wells, flowing wells, deep or shallow, the AS1-XHP is suited. The packer can be left in tension or compression, depending on well conditions and the required application.A large internal by-pass reduces swabbing when running and retrieving.The J-slot design allows easy setting and releasing; 1/4 turn right-hand set, right-hand release. A patented upper-slip releasing system reduces the force required to release the packer. A non directional slip is released first, making it easier to release the other slips. The AS1-XHP packer can withstand 10,000 psi (69 MPa) of differential pressure above or below.

Model “TST-1” Mechanical Set Packer

The PARVEEN TST-1 Retrievable Packer is a heavy duty service packer ideally suited for all types of squeeze cementing, formation fracturing, high pressure acidizing, etc. It is a large opening compression set packer with hydraulic button-type hold down. It withstands high pressure from above or below and uses a three-element packing system, L-slot, and a drag block mechanism for easy setting. The tool features a proven three element packing system and hydraulically controlled balance sleeve designed to keep the by-pass valve closed when set.

Its Features Include- Sets securely in any hardness casing, including premium grades,Three piece packing element systems with metal backups accommodate low and high pressure applications for the broadest range of services. Hydraulic hold down button unit with large internal flow path located below the bypass valve to reduce element swabbing and button wicker dulling. These hold down piston type slips are set by pressure from below.Surface controlled combination bypass and equalizing valve. Automatic L-slot Unit, setting the packer is accomplished by running to depth rotating 3/4 turns to the right and setting down.Straight pickup of the tubing will first open the bypass valve and equalize pressure continued pickup will release the packer and automatically engage the packer in the running position for further operations up or down the hole.All Thread connection comes standard in API IF/EUE thread form. All Pressure bearing o-rings for higher pressure resistance. Load and pressure resistance designed to meet high load applications.P110 body, coupling and sub for heavier duty jobs

ERD Retrievable Seal Bore Packer (Deviated Well)

PARVEEN Model ERD Retrievable Hydraulic Seal Bore Packer is a Retrievable Packer.Hydraulically set by pressure in the tubing. It is run with Hydraulic Setting Tool & retrieving is done independently from the Tubing, using a Retrieving Tool manipulated on a work string. This packer is ideally suited for highly deviated wells both onshore & offshore.This model is used in oil production wells or in water or gas injection wells.

Its Features, Advantages and Benefit includes- Run & set with the Production Tubing, the Hydraulic setting that eliminates the requirements for spacing out & opening & closing with the help of Sliding Sleeves for the displacement of fluids.Effects on tubing (compression & tension) are transmitted to slips- there is no shear ring with limits these stresses and Retrieval independent of the tubing using a Retrieving Tool. It can be lifted to the bottom of the well with a By-Pass Blanking Plug in a Nipple to isolate the formation.

RHP- DB Dual Bore Hydraulic Set Retrievable Packer

The PARVEEN MODEL RHP-DB Retrievable Packer delivers high performance with simplicity of design and desirable economics. The dual bore packer allows for a large ID through the packer by sealing in an upper seal bore. No tubing rotation required to fully set the packer. It has a one-piece, self energizing packing element and features bidirectional slips below the packing element for maximum protection from debris fouling. This location protects the slips from being lost during retrieval or milling. A retrieving tool is required to retrieve these packers.

Its features include-Simple design,Easy to retrieve,Large seal bore,Hydraulic setting and The ECNER array system.

Model DB Hydraulic Set Permanent Packer

PARVEEN Hydraulic-Set Dual Bore Permanent Production Packers are the hydraulically set one-trip completion packers, ideal for high volume production in high angle, extremely deviated well. These packers feature the largest possible bore through combined packer and seal accessory. The packer is run on the hydro-set anchor latch seal unit which is made up in the top of the packer via the left-hand threads on the latch and is set by applied tubing pressure. The DB packer requires some type of temporary plugging device such as a shear out plug or wireline blanking plug located close to the end of the tubing.

Its advantages include- Slim-line design,Solid construction,Two opposed sets of full-circle,Packing element,unique interlocking, expandable, metal backup rings contact casing,creating a positive barrier to packing element extrusion.

Model ‘D’ & ‘F’ Permanent Packers

PARVEEN’S Model ‘D’ & ‘F’ Production Packers are available to fit your needs and provide the versatility of our excellent pack-off system for a positive secure set in the well bore.These are designed to accommodate seal bore extensions used in deep wells requiring a longer seal bore interval. Seal Nipples are available with either automatic square-thread latch or locating shoulder. These packers can be used as test tools. Full opening bores allow the passage of perforating guns used to perforate a zone below for testing. If the zone proves to be non-productive, the packer can be used as a squeeze tool.

PARVEEN’S Model ‘D’ Production Packers provide excellent clearance for run-in while the PARVEEN’S Model ‘F ’Production Packers offer a larger seal bore. The two models carry different pressure ratings noted later in this document.

Its Features include-One piece slips hardened to depth of wicker only,Sets in any grade casing including P-10,Choice of bottom to fit your application – specified when ordering and Re-attaching lock ring holds setting force.

Mechanical Production Packers “sure-lok” Packer: (Large Bore)

The PARVEEN Large Bore “Sure-Lok” is a compression set, retrievable packer that allows the tubing to be left in a tension, compression, or neutral condition.Its features include- Internal by-pass,Opposed dovetail slips for positive set,Holds pressure from above or below,Can leave tubing in a tension, compression, or neutral condition,Right hand rotation sets and releases the packer retracted dovetail slips,Converts to mechanical bridge plug with the addition of a valve Optional packing element stems and Large Bore.

Completion Equipment

PARVEEN offers full set of downhole well completion strings with equipment like Fluted Swage, Adapters, Flow Coupling, Blast Joint, Cross Overs, Perforated Joints, Wireline Re-entry Guide, Pump Out Plug,Safety Valve Systems both Tubing and Wireline Retrievable,Expansion joints,Side Pocket Mandrels,Sliding Sleeves, Packers, Permanent & Retrievable Mechanical, Hydraulic, Landing Nipples both ported and non-ported and completion accessories like control lines, Banding Strap, Banding Buckles etc.