Wellheads & X-mas Trees, Gate Valves, Chokes, and Manifolds

A wellhead is used at the surface of an oil & gas well that provides the structural and pressure-containing interface for the drilling and production equipment. Christmas Tree is an assembly of valves, spools, pressure gauges, and chokes fitted to the wellhead of a completed well to control production. We offer these in a wide range of sizes and configurations, such as low – or high–pressure capacity. Variety of Valves, Chokes, and Manifold also form our core offerings.

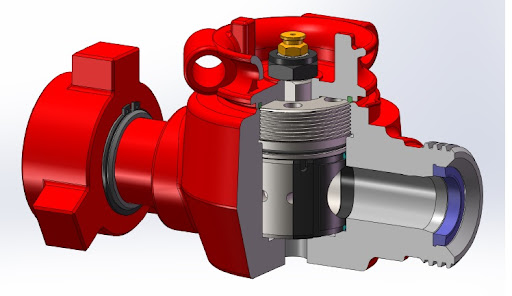

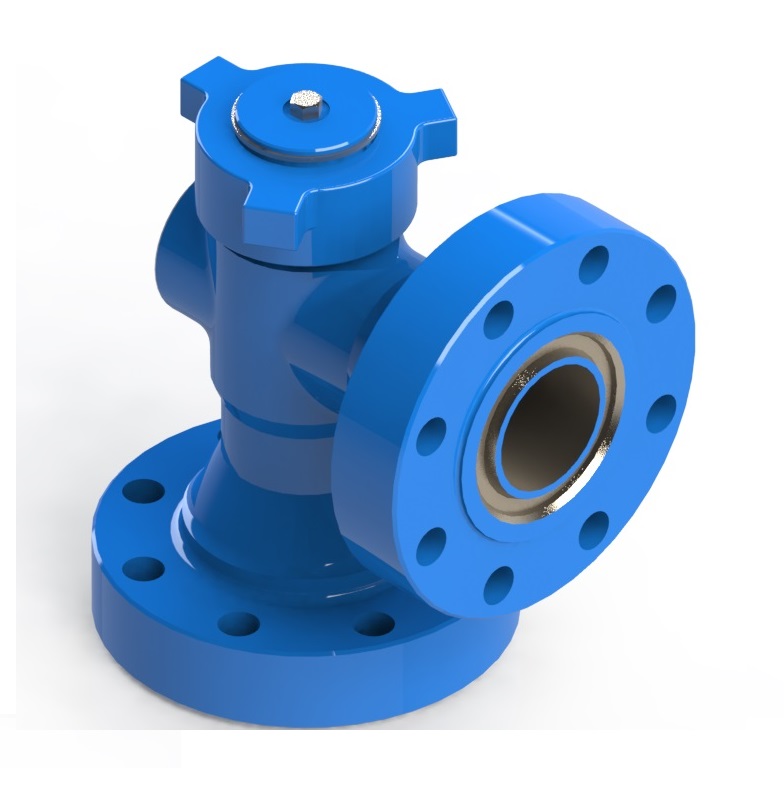

Plug Valves

The PARVEEN TE Plug Valve is a lubricated, straight pocket, quarter-turn plug valve for rapid full open or close operation. The valve cavity is straight to ensure the low-torque operation and uniform sealing of the components at the full range of pressures. Inserts are provided with a dual seal. The PARVEEN TE Plug Valve and replacement parts are engineered to provide low operating torque and resistance to the toughest abrasive and corrosive conditions.

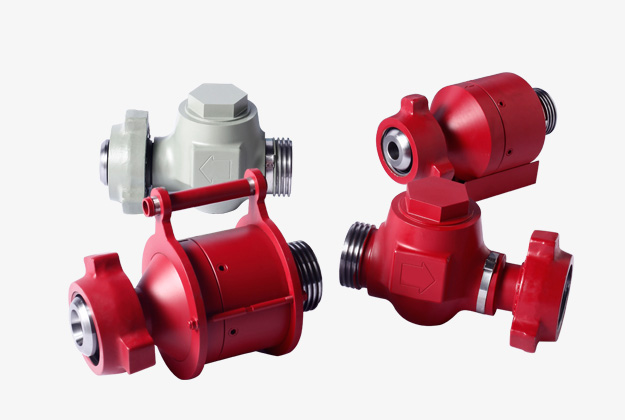

Choke Valve

PARVEEN manufactures both Positive and Adjustable Chokes in pressure rating up to 15,000 PSI WP., with different styles of end connection.

Adjustable Chokes are meant for variable flow. They have an externally controlled indicator showing orifice size in the increment of 1/64 inch. The variation in choke size is achieved by rotating the handwheel to obtain desired flow rate at down stream side.

Check Valves

Parveen Check Valves are flow control devices that permit flow in one direction, but stop flow in the opposite direction. These valves are used generally in well service applications and are placed in the treating line to allow flow to the well, but isolate any backflow.

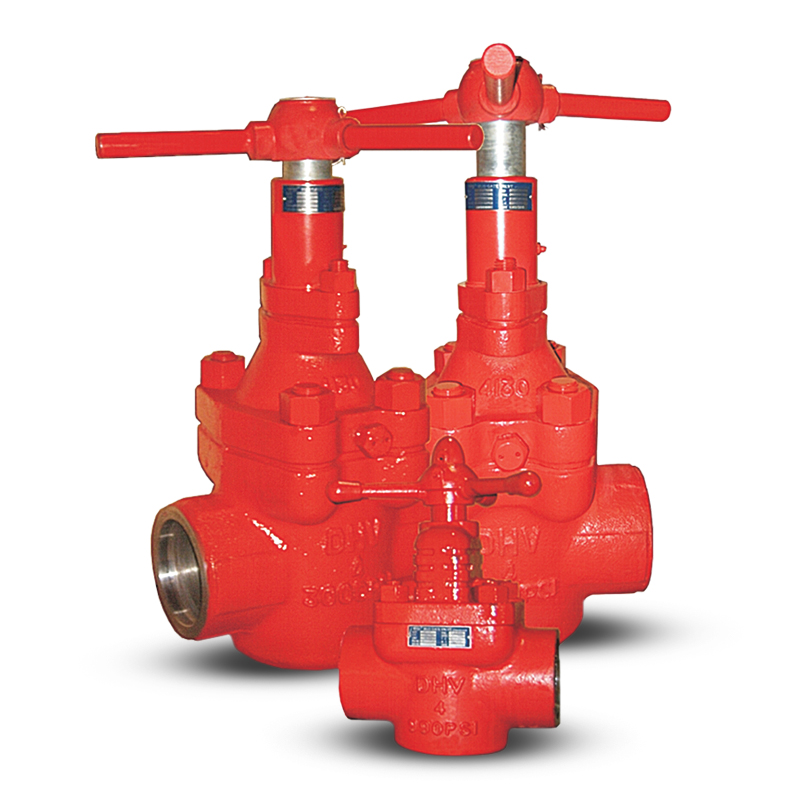

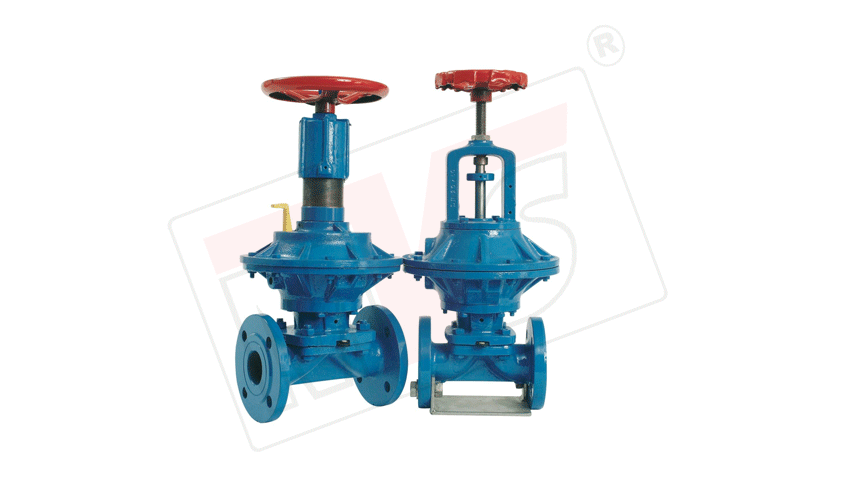

Mud Gate Valves

PARVEEN Mud Gate Valves are Forged exclusively made for mud, cement, fracturing, water & steam abrasive, and shipyard applications. All valves are hydrostatic shell and seat tested in accordance with the API 6A specifications. Valves are specially designed for oil-field applications like Wellheads, Manifolds, Pipe Line, Crude oil and Sour gas line, Well treating chemical, Drilling Chemical, Waterflood lines, Abrasive drilling mud & shipyard, etc. Valves are available up to 10,000 PSI WP. These can be certified by ABS / DNV offshore or any other third-party inspection.

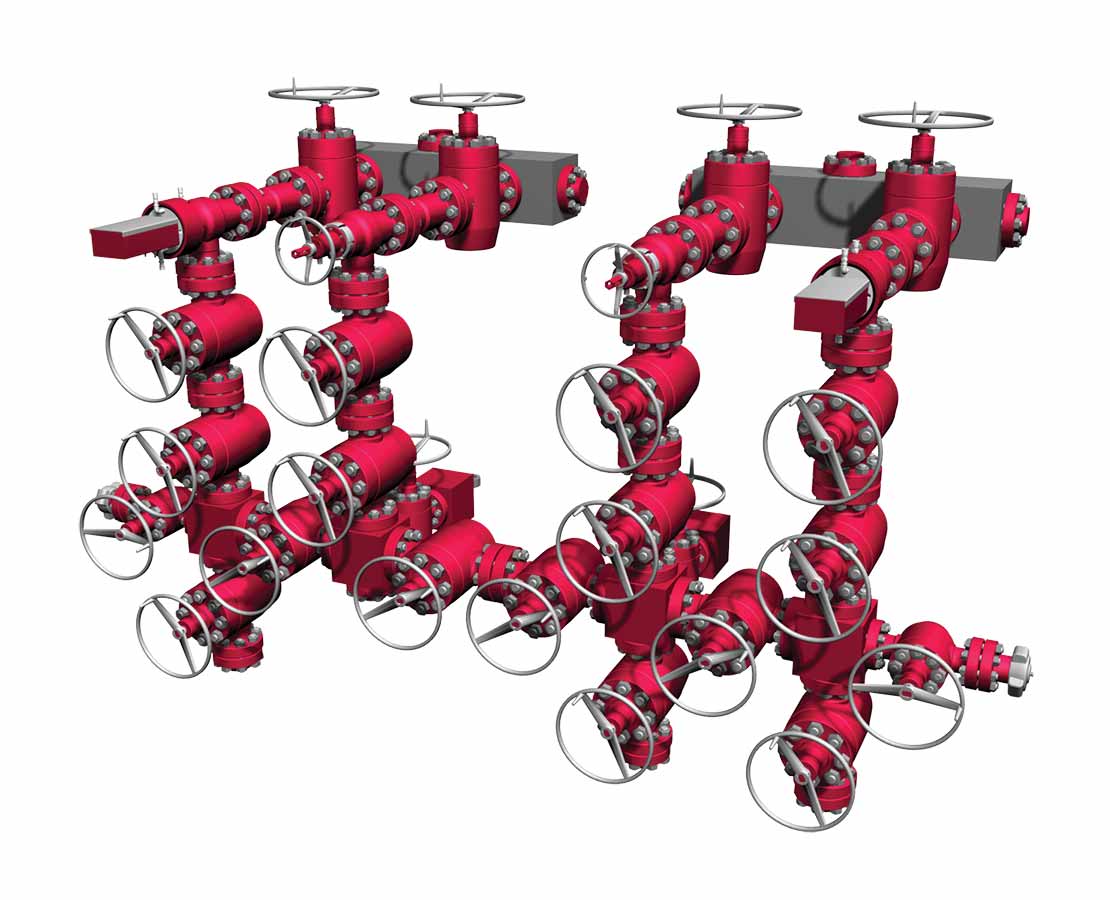

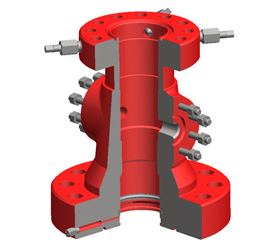

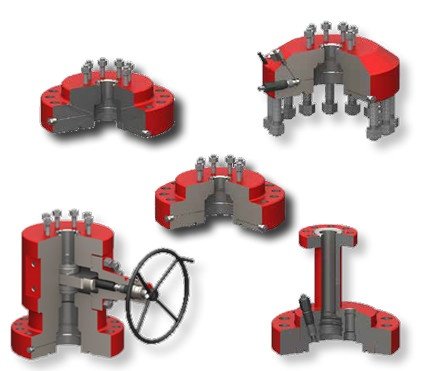

Choke And Kill Manifolds

PARVEEN fabricates custom-designed Choke and Kill Manifold : In oil/gas well drilling operations, drilling fluids (muds) of designed gravity are used to overcome sub-surface pressure or the influx of formation fluid. On some occasions, kicks are experienced with a change in pressure of formation while drilling. And, For Well Testing / Completion / Intervention, the industry uses various configurations of Manifold, as per the requirement of Service / Operating Companies, PARVEEN designs and fabricates custom made Manifold in sizes of 2” to 4” up to 15,000 PSI for standard and sour services.

Mud Valves

PARVEEN Mud Valves are Forged/Cast exclusively made for mud, cement, fracturing water, and steam abrasive applications. All valves are hydrostatic shell and seat tested in accordance with the API 6A /API 6D specifications. Valves are specially designed for oil-field applications like Manifolds, Pipe Line, Crude Oil, and Sour Gas Line, Well Treating chemicals, Drilling chemicals, Water Flood Lines, Abrasive Drilling Mud, etc.

Frac Manifold

Typical components of a frac manifold include spools, tees, crosses, gate valves, and goat heads. These are assembled into various configurations to suit the number and spacing of wells being simultaneously serviced, the planned arrangement of the frac lines, the extent to which actuation is desired, etc. Parveen’s frac manifolds may also be equipped with a safety ladder and platform to provide safe access to the valves.

Frac Tree

Parveen tree is built to reduce bending stress at the tree connection and can be operated with pneumatic, hydraulic, or electric actuation.

The horizontal tree represents a more than 50% reduction in size and about 25% in weight from our first conventional frac tree. It is short, stable, and easily anchored – an ideal configuration for frac-tree service. The 90° goat head is located at the end of the horizontal section, resulting in the distance across which the bending loads act being less than half of that of a conventional stacked-valve frac tree.

Frac Equipment

These are the equipment often used on frac tree and frac stacks during fracturing work, which is often in studded and flange-end connections. The Frac Head reduces the risks normally associated with using substandard equipment.

For sour gas services and to withstand the damaging effects due to both Hydrogen Sulfide (H2S) and Carbon Dioxide (CO2) gases are provided to assemble with stainless steel ring gaskets. In addition; the PARVEEN Frac Head is machined from solid raw material and hardened alloy steel, making it more durable and safer for high-pressure service.

Flanges

PARVEEN is a manufacturer of various types of Flanges and Pipe Fittings required by the oil field, petrochemical, and different process industries. Our name is synonymous with high-quality manufacture, precision machining, and unparalleled dedication to quality. Excellence has kept us at the forefront of the oil industry.

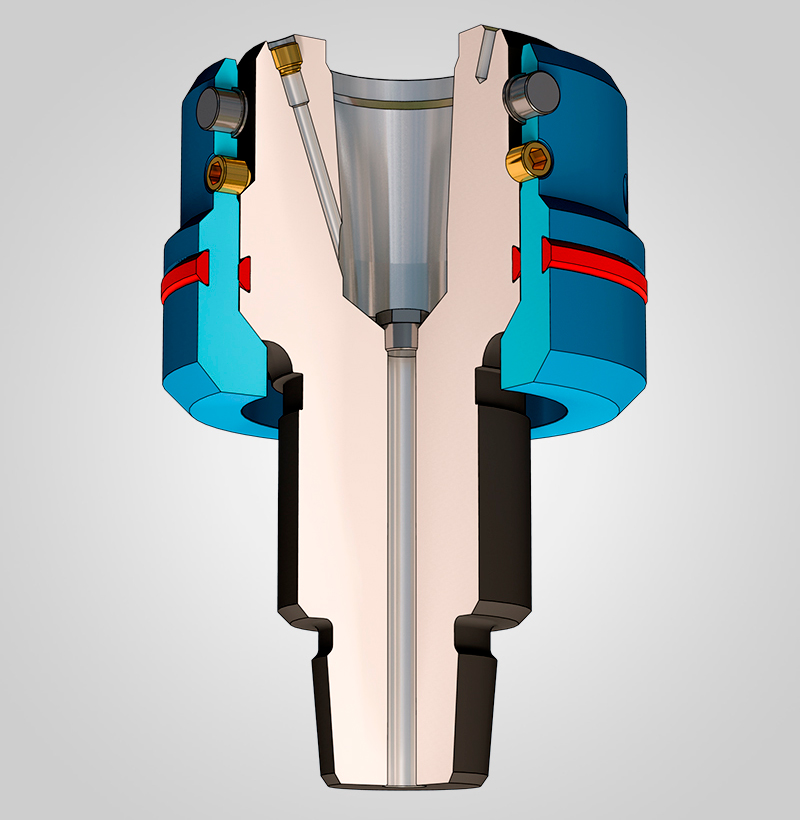

Cementing Head

PARVEEN Cementing Head is used for cementing the annular space between The casing and bore hole during the 2nd stage of the good construction cycle. The Cementing Head is employed to connect the pumps of the cementing trucks to the casing string and provides access for insertion of the cementing plugs. PARVEEN’s Cementing Heads are available in sizes 4 1/2 ” to 20”, for a working pressure of 2,000 to 10,000 PSI.

Single Completion Component

PARVEEN also manufactures different types of Single Completion Components as per API-6A or customer specification. Multiple Completion Components (e.g. Dual Manifold Tee, Dual Adapter Flange, Dual Completion Flanges, Multiple Completion Sub Seal, etc.) can also be provided upon request.

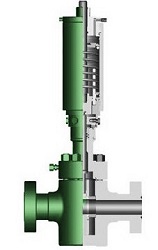

PHDC 01 Hydraulic Drilling Choke With Control Panel

The Hydraulic Choke is a hydraulically operated variable choke providing any opening from a maximum of 1.93 square inches (1 9/16” equivalent bean diameter) to full shut off. The working pressure rating of the choke is 10,000 PSI. Two Tungsten Carbide discs, each with a semi-circular opening, form the choke. Various openings are obtained by rotating the upstream disc against the stationary downstream disc.

Type Target Choke Valve

These are used in many oilfield applications to control the rate of flow. Usually, an adjustable choke is used as part of a manifold installed downstream of the wellhead. The choke is adjusted during the flow back of the well to control downstream pressure and flow rates. The PARVEEN adjustable choke is comprised of three main sub-assemblies. These sub-assemblies are the bonnet, tee, and nipple assemblies.

PARVEEN chokes are available in 3/4”, 1”, and 2” maximum orifice sizes with Fig. 602-1502 hammer union connection.

Positive Choke Valve

Positive Chokes accommodate fixed orifice dimensions. All PARVEEN Adjustable Chokes can be converted into Positive Chokes by replacing the bonnet assembly with an appropriate blanking plug assembly and choke bean. These are manufactured up to 7″, 15,000 PSI with all types of end connections.

External Sleeve Choke Valve

PARVEEN External Sleeve Control Chokes minimize erosion and improve flow characteristics suitably for erosive service and under the high-pressure drop, with sand concentration. It applies the principle of “Flow Impingement” to dissipate and contain the destructive forces of cavitation, within the heavy-duty thick-walled cage of Tungsten Carbide.

Pneumatic Diaphragm Operated Gate Valve

Pneumatic Diaphragm Gate Valve has less friction, close-open quickly, long life, and dependable sealing. It could be an SSV (Surface Safety Valve) with an Induction System, driven by compressed air. When the fluid pressure in the pipeline has some troubles, it will be auto-off, and it could auto-off the main valve while controlling system pressure blabbed. This valve has been installed with the manual pressure relief device, overpressure auto protector, and manually operated device.

Surface Safety Valve With Hydraulic Actuator (SSV)

PARVEEN type actuator is a fail close hydraulic actuator. The actuator is operated by hydraulic pressure applied through a static piston on a translating cylinder. The cylinder actuated by hydraulic pressure compresses the spring by an upper spring retainer plate and directs the bonnet stem and gate into the open position. Should the hydraulic pressure within the cylinder/piston be vented, the spring arrangement ensures an instantaneous valve closure regardless of line pressure.

A spring arrangement, piston & hydraulic cylinder are assembled in a single package enclosed in housing by dual spring plates positioned within a flange and a location shoulder. The actuator assembly is easily removable from the valve for maintenance, actuator replacement, or transportation. Hexagonal screws on the lower plate & a threaded The connection between the traveling cylinder & stem keeps the actuator connected to the valve.

High-Temperature Gate Valve

The PARVEEN High-Temperature Gate Valve uses a parallel expanding gate to obtain a perfect shut-off. The sealing is metal – to metal, both on the up and downstream of the valve, and unaffected by vibration and heat. The valve is the standard Model ‘E’ gate valve, modified with an extended bonnet and stem to place the stem packing outside the critical heat zone. Other features and trim charts shall remain the same for model ‘E’ gate valves.

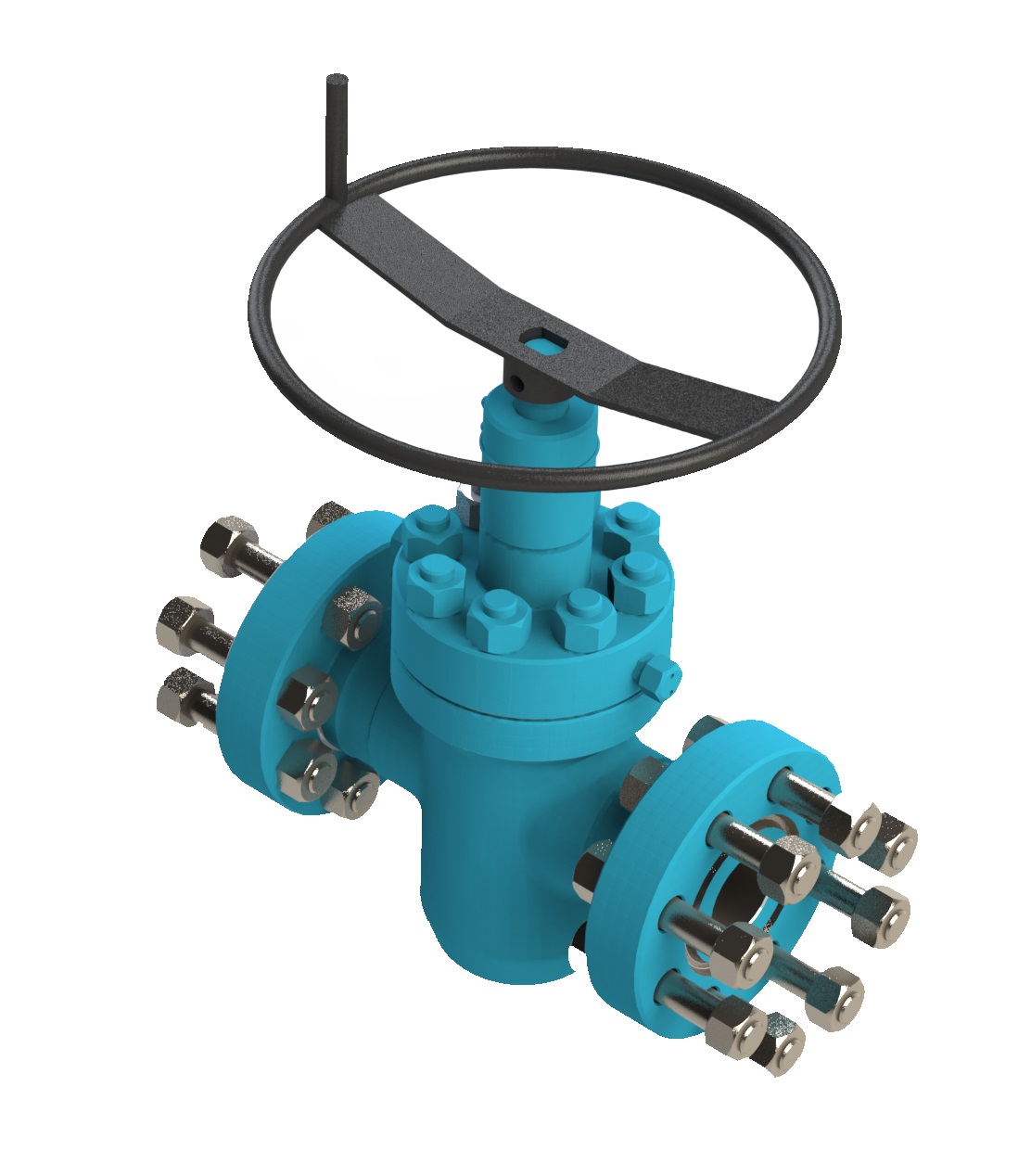

Slab Style Gate Valve

PARVEEN Slab Style Gate Valve consist of Handwheel Assembly, Bearing Cap, Grease Fitting, O-ring, Bearing Race, Thrust Bearing, O-ring, Stem Adapter, Stem Pin,packing Gland,‘j’ Packing, Nut, Stud, Bonnet, Grease Fitting, Gasket, Stem, Gate, Retainer Plate, Seat Ring, Seal Ring (Seat Ring), Pin, Body, Guide, Seal Ring (Body Bushing), Body Bushing, Name Plate.

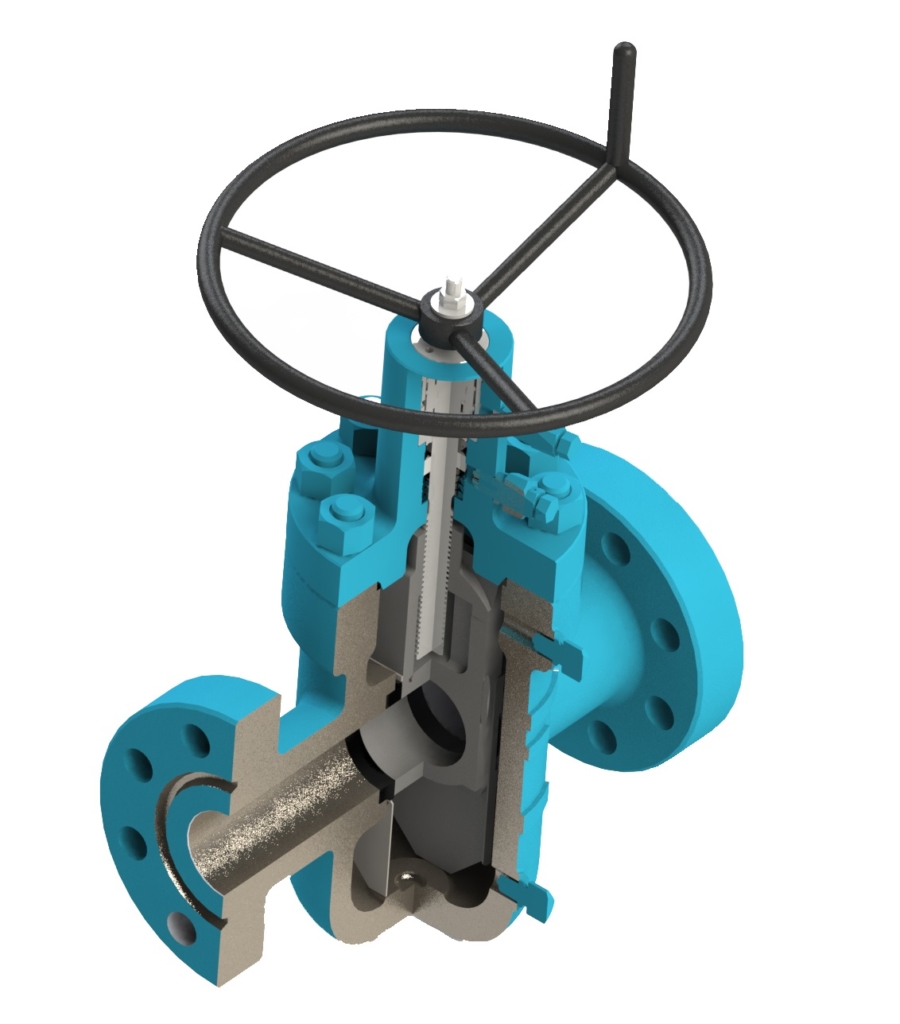

Expanding Style Gate Valve

PARVEEN manufactured Gate Valves required for drilling and production operation.

Part List Flanged Gate Valve (Model – M) includes Body, Body Grease Fitting, Seat Assy., Seat, Teflon/t.f.e. Ring, Gate Segment Assy., Gate, Segment, Spring, Gate Pin, Gate Guide, Bonnet, Bonnet Seal Ring, Packing Fitting, Bonnet Grease Fitting, Stud With Nut, Packing Set, Header Packing Ring, ‘v’ Packing Ring, Packing Retainer Bushing, Bearing Spacer Sleeve, Thrust Bearing, Stem, Bearing Retainer Nut, Bearing Retainer Lock Nut, Handwheel, Handwheel Nut, Washer For Handwheel Nut.

Tubing Head For CBM Wells

The Parveen Tubing Head is made from steel and uses a tubing hanger w/o-rings, & a top-end tubing adapter. These heads are suited for wells with working pressure up to 5000 PSI and allow string suspensions, with all sizes being a full opening.

Casing Head For CBM Wells

Coal bed methane (CBM), coal seam gas ((CSG), or coal mine methane (CMM) is a form of natural gas extracted from coal beds. It is generally sweet but may contain a few percent of carbon dioxide.

Parveen manufacture and supplies surface wellheads and other surface equipment for the extraction of CBM. The Parveen Casing Head is made from steel and uses three packing rings. These heads are suited for wells with working pressure up to 2000 PSI and allow string suspensions, with all sizes being full opening.

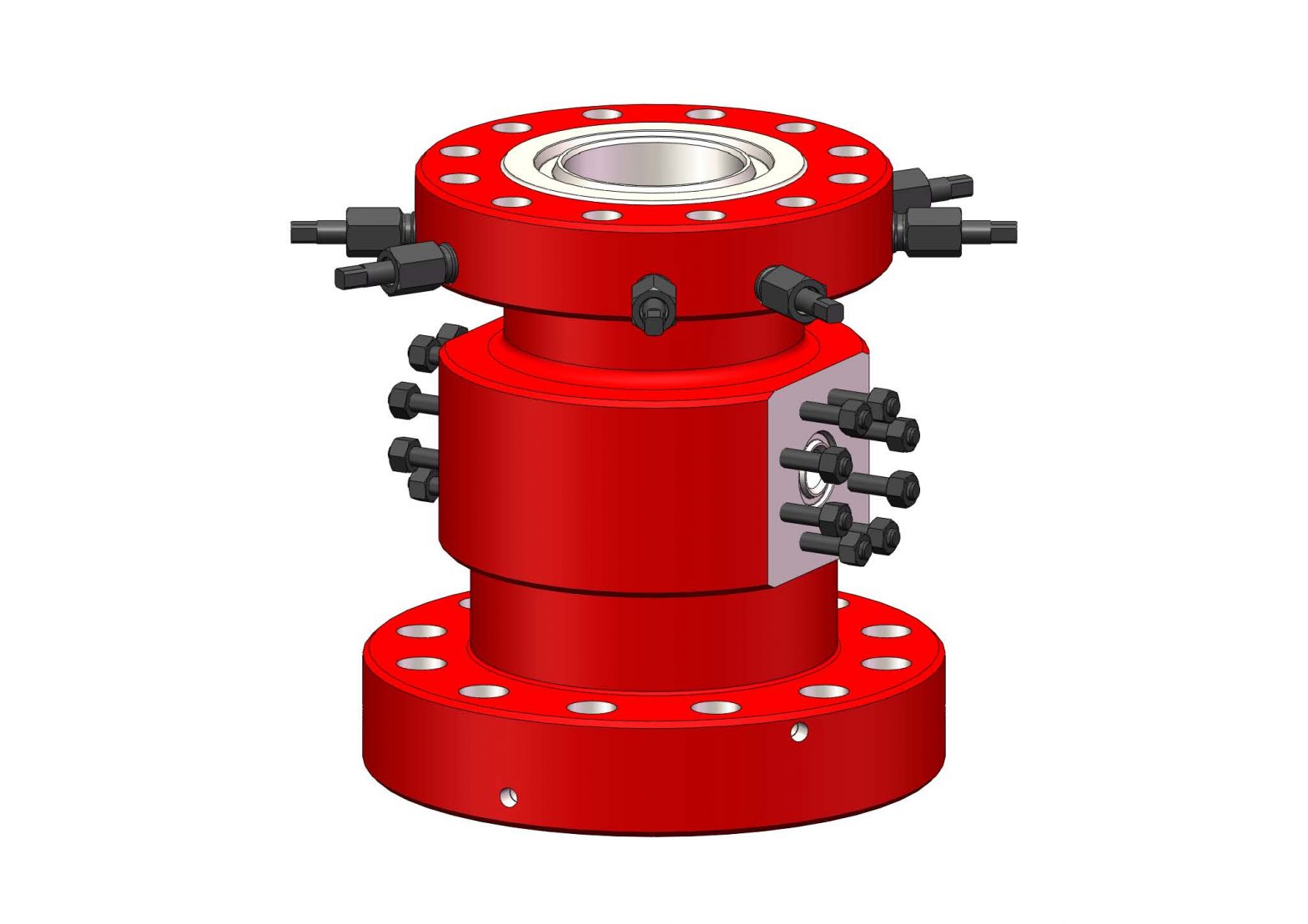

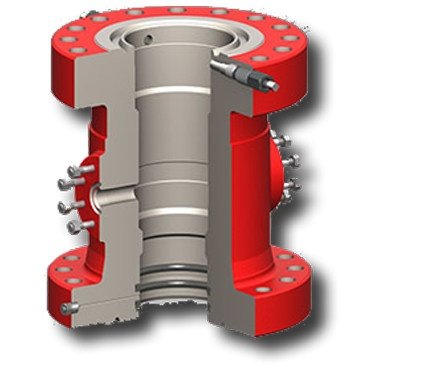

Unitized Wellhead Assembly

Unitized Wellhead Assembly includes Test Plug / Running & Retrieving Tool Of Wear Bushing (Combination Tool), Wear Bushing (Bore Protector, Clamp Bolts, Nuts, Tubing Head Adapter / Bonnet, Clamp, Clamp Bolts and Nuts, Tubing Hanger Pack-Off Assembly, Tubing Hanger, Support Ring, Mandrel Casing Hanger Pack-Off Assembly, Mandrel Casing Hanger, Multibowl Head, Mandrel Casing Hanger Pack-Off Assembly, Mandrel Casing Hanger, Casing Head, Clamp, Slips, Studs & Nuts.

Wellhead Tools & Service Equipment

Wellhead Tools & Service Equipment includes Wear Brushing, BOP Test Plug (PTP), PARVEEN X-Mas Tree Cap, Back Pressure Valve (BPV), Two Way Check Valve (TWCV), Lubricator (PL), Flanged Drilling Spool (PFDS), Valve Removal Plugs (PVRP), Valve Removal Lubricator (PVRL).

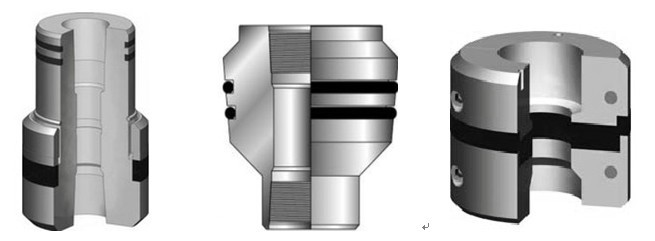

Seals

Type ‘FS’ Seals (Secondary Seals) Type FS Casing & Tubing Seal has been developed for arduous duties where there are large clearances between mating parts of wellhead and associated assemblies. It has been tested in accordance with API requirements for use on the surface wellhead to casing systems, where the seal can readily replace the metal end cap and plastic pack sealing arrangement.

Type ‘P’ Seals (Secondary Seals) is an elastomer seal comprised of an injectable, formed seal ring flanked by two anti-extrusion rings. A single seal is recommended for pressures up to 5,000 psi. Used in a double seal configuration, and depending on the size of the seal, the Double P seal can be rated up to 15,000 psi. This easy-to-install, reliable, and field-proven design is one of PARVEEN’s standard, integral, elastomer seals offered with conventional equipment.

Tubing Head Adapters

The tubing head adapter provides a transition between the Christmas tree and the tubing head. The bottom adapter connection matches the tubing head and the top adapter connection matches the tree. Tubing head adapters are available for all types of single- and multiple-string completions, including those using electric submersible pumps, packers, downhole control valves, and gas lift valves. These adapters come with threaded, flanged, or studded-flanged top connections. Most tubing head adapters are available with hydraulic supply inlets for downhole control lines. If the customer requires, PARVEEN also supplies various types of adapters that will accommodate continuous control-line capabilities.

It Provides sealing bore for a variety of electrical feed-thru configurations, including penetrators, cable pickoffs, and continuous feed-thru penetrator mandrels. Also, it has reliable seal bores for tubing hanger neck or seal sleeves.

Tubing Hanger

Tubing hangers are installed in the top bowl of a tubing head. Tubing hangers both suspend tubing and provide a primary annulus seal between the tubing and production casing. Hangers are run through the blowout preventers and are landed in the top bowl of the tubing head. Tubing hangers also act as a means to access and manipulate additional smaller tubing lines that are utilized downhole and extended to the surface on the outside of the tubing string or strings.

PARVEEN Surface Wellhead type TC-Series tubing hangers are available for any type of single- or multiple-string tubing completion, including those requiring packers, subsurface safety valves, gas lift valves, and electric submersible pumps. All PARVEEN Surface Wellhead hangers can be run through the blowout preventers, allowing the well to be secured before the preventers are removed. Most type TC-Series tubing hangers accept a back-pressure valve, which seals the tubing bore. Some hangers are ported for hydraulic control lines, downhole safety valves, or other equipment as required by the customer.

Tubing Heads

The tubing head is the top spool on a surface wellhead assembly. It is installed after the last casing string to provide a load shoulder to support the tubing string and a seal bore for the tubing hanger or production casing/tubing annulus seal. When the well is completed, the tree is installed on top of the tubing head with a tubing head adapter.

“Wedge locking” of bowl protector, BOP test plugs, and tubing hangers is eliminated, Seal bore is less likely to be damaged during drilling, It’s more economical to recondition after abandon.

Double Studded Pack off Flange

Double Studded Pack off Flange, provides a double” P” or “FS” seal for sealing the casing. The double studded pickoff flange is also used as an intermediate crossover flange when a restricted area is used in the smaller diameter top groove. When a crossover is used, the top connection can be exposed to a higher pressure than the original rated working pressure. The double molded elastomer P seals are energized by injecting the high-pressure grease/plastic packing.

Slip Type Casing Hanger

Slip-type casing hangers provide a method to transfer the weight or tension load of a casing string to a casing head or casing spool. Slip-type hangers are available in automatic-sealing and nonautomatic-sealing varieties. Automatic hangers have seals that are energized by casing weight, while nonautomatic hangers have seals that require means other than casing weight to be energized. Nonautomatic hangers are typically used when insufficient casing load is available or when cementing back to the surface.

It Provides easy wraparound or split installation at any location on the casing string, Also provides suspension of the casing load from a casing head or spool, It gives the means to center the casing string in the head or spool.

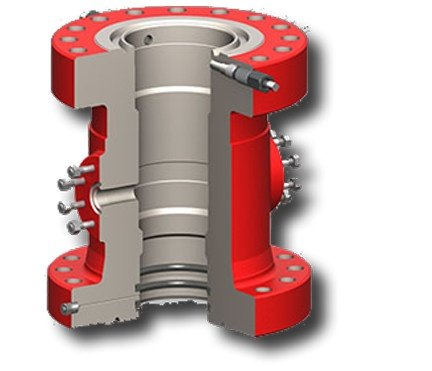

Casing Spools

The casing spool has a top bowl to accommodate the casing hanger. The spool also has a bottom bowl with a pack-off seal and a flange or clamp hub for mounting it on top of a casing head or previous spool. Outlets are provided for annular access. Multiple casing spools may be stacked to hang intermediate and production casing strings.

Straight bowl prevents wedge-locking of bowl protectors, casing hangers, and test plugs. Also, Type C-22-EG reduces the number of leak paths, lowers cost, and increases safety

Casing Heads

The casing head is the lowest part of the wellhead assembly and is connected to the surface casing string. It supports subsequent drilling wellhead and completion equipment.

Casing Heads provides for attachment to the surface casing string, Supports blowout preventers while the hole is drilled for the next casing string. Also, provides for suspending and packing off the next casing string and outlets for annular access. It’s useful for testing BOP’s while drilling.